When you're shopping for contactors, mixing up AC and DC types can lead to equipment failure, safety risks, or wasted costs. Many buyers know contactors control power flow, but few clear up the core differences that matter for their specific needs. This guide breaks down those critical distinctions simply, so you can choose the right one for your project.

1. How They Work: Core Principle Differences

The biggest divide starts with how each contactor handles current flow—rooted in the nature of AC (alternating current) and DC (direct current) themselves.

DC contactors deal with current that flows in one steady direction, with no zero-crossing. Without this natural pause, stopping the current requires more intentional design to avoid issues like arcing.

AC contactors work with current that reverses direction regularly. This reversal creates a "natural zero-crossing" point where current drops to zero briefly. This feature simplifies how the contactor turns power on and off.

2. Arc Suppression: A Make-or-Break Feature

Arcing (the spark when contacts open or close) is a major concern for contactor longevity and safety—and AC and DC contactors handle it very differently.

DC contactors need specialized arc suppression. Since there's no zero-crossing, arcs last longer and are hotter. These contactors use designs like magnetic blowouts (magnets that pull arcs away from contacts) or advanced arc-quenching materials to quench sparks quickly, protecting the contacts and preventing overheating.

AC contactors rely on the natural zero-crossing to suppress arcs. When the current hits zero, the arc extinguishes on its own. Most AC models only need basic arc chambers (like metal grids) to manage any remaining spark.

3. Coil Design and Power Requirements

The coil (the part that creates the magnetic force to move contacts) is another area of clear difference, affecting how you power and maintain the contactor.

DC contactor coils use solid iron cores. Since DC current is steady, there are no eddy currents to worry about—so a solid core works efficiently. These coils also draw a consistent current, unlike AC coils (which can have higher inrush current when first turned on).

AC contactor coils often use laminated iron cores. AC current creates "eddy currents" (wasted energy) in solid metal, so laminations reduce this loss. These coils also may have a "shading ring" to prevent humming (a common issue with AC magnetic components).

4. Where They're Used: Application Differences

Knowing which contactor fits your use case comes down to the type of power your equipment runs on—and the demands of that environment.

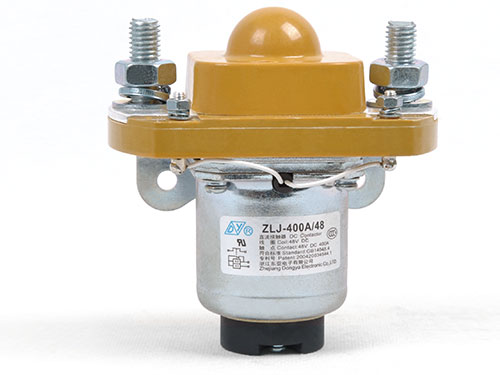

DC contactors are key for DC-powered systems, like electric vehicles (EVs), solar PV setups, battery storage, and industrial equipment that uses DC power (e.g., some robotics or telecom gear). These systems need the arc suppression and steady current handling that DC models provide.

AC contactors are everywhere in everyday and industrial AC systems: home appliances (fridges, air conditioners), electric motors (in factories or HVAC), and power distribution for buildings. They're ideal for systems where current reverses regularly.

How to Pick the Right One

To choose between AC and DC contactors, ask yourself three questions:

1. Does my equipment use AC or DC power?

2. Will the contactor face frequent on/off cycles (needing strong arc suppression)?

3. What power supply do I have for the coil? Answering these avoids mismatches—and ensures your equipment runs safely and reliably.

If you're looking for contactors tailored to either DC applications—whether for industrial setups, renewable energy, or other projects—Explore Our Product Page to find models designed for your specific needs.

English

English  한국어

한국어