Lots of folks struggle to tell different DC contactors apart, especially when selecting parts for high-power systems. Getting clear on how specialized and standard options differ helps avoid missteps in setup and use—mistakes that can trigger equipment damage, safety risks, and unplanned downtime. Let’s break this down simply.

Key Distinctions in Design

Insulation Systems

Standard DC contactors rely on basic insulation materials, designed for low to medium voltage ranges. High-voltage models demand upgraded insulation—usually high-performance composites resistant to temperature fluctuations—that withstands much bigger voltage spikes without failing. This isn’t just an upgrade; it’s a safety necessity, preventing electrical leakage and equipment burnout under extreme electrical stress.

Arc Suppression Mechanisms

Arcs are more dangerous and longer-lasting in high-voltage circuits. Left unchecked, they can melt contacts, start fires, and degrade system performance over time. Standard contactors use simple magnetic arc blowouts or chutes. High-voltage variants incorporate advanced arc suppression systems—like vacuum chambers or gas-filled enclosures—to snuff out arcs fast and protect contacts from damage.

Where Each Excels in Real-World Use

Standard DC Contactor Applications

Standard models shine in low-power setups. Think small battery systems, household appliances, and low-voltage industrial controls—places where voltage demands stay steady and low, with minimal electrical stress on components.

High-Power Scenarios for Specialized Contactors

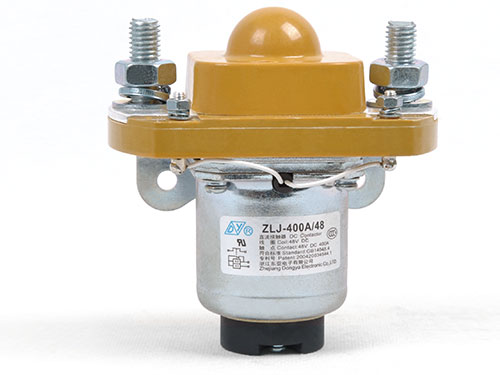

High-voltage models are non-negotiable for systems running at hundreds of volts or more, often between 400V and 1500V in common industrial use. They’re critical for maintaining consistent operation in heavy-duty setups like electric vehicle powertrains, large-scale solar storage, and industrial backup power systems—where voltage stability and safety can’t be compromised, and downtime is costly.

Critical Factors for Selection

Voltage and Current Ratings

Standard contactors come with lower voltage ratings, usually below 200V DC, with moderate current capacity. High-voltage units, though, are rated for 400V DC and up, with current limits tailored to high-power loads—so they withstand peak demands without breaking down.

Durability and Lifespan

In high-voltage setups, contactors wear down faster due to electrical stress and arc erosion. That’s why specialized high-voltage units are built with rugged materials and reinforced contacts to resist this wear—they last longer and need less frequent replacement than standard models in the same high-demand conditions, reducing long-term maintenance costs.

Conclusion

Understanding the gap between these two contactor types ensures you pick the right part for your system. Standard contactors work for low-voltage, low-power jobs; high-voltage ones are engineered for safety and performance in high-power setups.

To find a High Voltage DC Contactor or DC Contactor that fits your system’s exact needs, head to our product page—you'll find options built for DC contactor reliability.

English

English  한국어

한국어