When working with DC-powered systems like EV charging or solar setups, many people encounter DC Contactor but have wrong ideas about it. These myths can lead to poor choices in selection or maintenance, harming system safety and performance. Let’s break down common misunderstandings and clarify the facts.

Myth 1 – DC Contactor Is Just a "Bigger Ordinary Switch"

The Key Difference Is Specialized Design

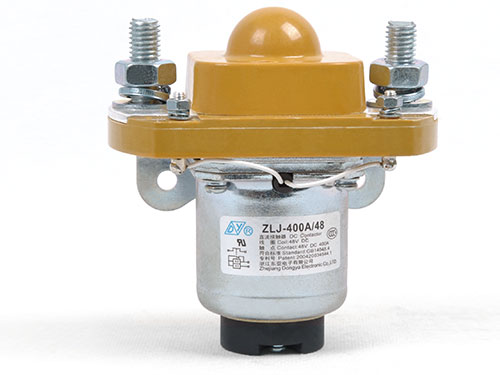

A regular switch works for small, low-voltage DC loads (like a flashlight), but DC Contactor is built for high-power use. Unlike ordinary switches, it has an arc-extinguishing structure. When high-current DC circuits disconnect, electric arcs form—these can damage parts or cause fires. This component uses uses heat-resistant copper alloys and magnetic arc blowers to quickly put out arcs, ensuring safe operation under heavy loads.

It Handles Steady High Loads, Not Just On/Off

Ordinary switches overheat or wear out fast with high currents (over 50A). This component is engineered to stay stable under continuous high power, with thickened contacts and heat-dissipating casings. This makes it fit for long-term use in systems needing consistent power transmission.

Myth 2 – Any DC Contactor Works for All DC Applications

Voltage and Current Ratings Must Match

This component has specific voltage and current ratings—no universal fit. For example:

A 12V automotive DC Contactor fails in a 400V solar inverter; its insulation can’t handle the voltage and may cause short circuits.

A 100A model can’t handle 200A EV charging; contacts will melt from excess current.

Choose based on your system’s exact voltage and current, not just "being a DC Contactor."

Environmental Factors Matter

Different applications need different protections. Indoor communication models don’t need the same dustproof, waterproof, or anti-vibration design as outdoor EV charging versions. Using a non-adapted model shortens its lifespan.

Myth 3 – DC Contactor Needs No Maintenance If It Works

Contact Wear Is a Hidden Risk

Even working units see contact wear with each on/off cycle. Worn contacts create higher resistance, causing overheating. In severe cases, contacts stick, leaving circuits on permanently—a safety hazard. Regular checks (inspecting contact thickness or discoloration) prevent this.

Insulation Degradation Needs Monitoring

Insulation materials in these devices degrade over time from heat, humidity, or chemicals. Poor insulation risks current leakage, damaging parts or causing shocks. Simple tests (like measuring insulation resistance with a multimeter) catch issues early.

Conclusion

Clearing these myths helps you make smarter choices, whether selecting a DC Contactor or maintaining systems. Remember: it’s a specialized component, not a "one-size-fits-all" switch, and needs regular care for safety.

If you need a DC Contactor for your application—from EV charging to solar systems—our product page has options tailored to different voltage, current, and environmental needs. Explore detailed specs there to find the right fit.

English

English  한국어

한국어