When working with electrical control systems, a question often arises: Can AC contactors be used with DC? Although AC (AC) and DC (DC) contactors look similar, they are designed differently to handle specific electrical characteristics. Using an AC contactor with DC can cause performance issues or even equipment failure.

This article explores the differences between AC and DC contactors, why they are not interchangeable, and when to use a **DC contactor**

Key Differences Between AC and DC Contactors

1. Arc Extinguishing Mechanism

AC Contactor:

AC current naturally crosses zero 100/120 times per second (50/60Hz), making arc extinguishing easier.

A simple arc extinguishing grid or shunt plate is usually used to extinguish the arc.

DC Contactor:

DC current has no zero crossing, so the arc is more difficult to interrupt.

A stronger magnetic blowout or special arc extinguishing chamber is required to break the current.

2. Coil Design and Power Consumption

AC Coils:

Rely on inductance to maintain magnetic force, resulting in lower power consumption.

Due to lack of inductive reactance, may overheat if used with DC.

DC Coils:

Use pure resistance, requiring a steady current.

More energy efficient for DC applications.

3. Contact Materials and Lifespan

AC Contacts:

Often made of a silver alloy optimized for AC switching.

May wear faster with DC due to sustained arcing.

DC Contacts:

Use harder materials such as silver tungsten or silver cadmium oxide to withstand DC arcs.

Designed for higher breaking capacity in DC circuits.

Why AC Contactors Should Not Be Used for DC

1. Risk of Contact Welding – DC arcs are more persistent, increasing the likelihood of contact welding.

2. Overheating and Coil Damage – AC coils may burn out under sustained DC voltage.

3. Poor Arc Extinguishing – Without proper arc suppression, DC currents may damage the contactor and its connected equipment.

4. Shortened lifespan – Frequent switching under DC conditions accelerates wear.

When is a DC contactor needed?

DC contactors are critical in the following areas:

Electric vehicles (BEVs, forklifts) – high current DC switching in battery systems.

Solar and battery energy storage – managing DC power from PV panels and energy storage systems.

Industrial machinery and UPS systems – reliable DC circuit control in critical applications.

Marine and telecom power systems – ensuring safe DC power distribution.

Conclusion

Although AC and DC contactors look similar, their internal designs are optimized for different current types. Using AC contactors in DC applications can lead to malfunctions, safety hazards, and increased maintenance costs. For reliable DC switching, be sure to select the best DC contactor designed for the required voltage and current range.

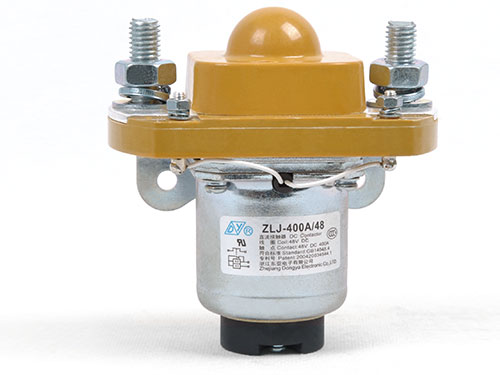

Zhejiang Dongya Electronics Co., Ltd. —With 20 years of expertise in energy storage electrical components, we deliver highly reliable DC contactors, relays, shunts, hydraulic circuit breakers, and BDU modules. Our full range of products is certified to UL/TUV/CE/CCC international standards and backed by 20+ patented technologies. Serving 300+ global energy storage clients, we provide rapid response, customized solutions, and 24/7 technical support to ensure safe and efficient energy storage system operation!

English

English  한국어

한국어