As electric vehicles (EVs) become more popular, the need for efficient and reliable EV charging infrastructure is growing. A key component in a DC fast charging system is the **DC contactor**, which ensures safe and efficient power transfer. Selecting the right DC contactor is critical for performance, safety, and longevity.

This guide will cover key factors to consider when selecting a DC contactor for EV charging applications.

What is a DC contactor?

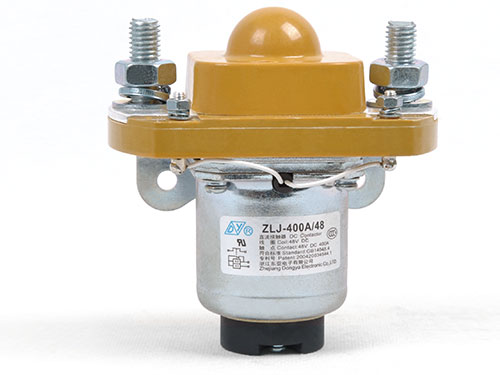

A DC contactor is an electrically controlled switch used to manage high-voltage DC circuits. Unlike AC contactors, DC contactors are designed to handle DC power, which presents some unique challenges, such as arcing and higher resistive losses.

In an EV charging system, a DC contactor:

Enables or interrupts the flow of electricity between the charger and the vehicle battery.

Provides overload and short-circuit protection.

Ensures safe disconnection during faults or maintenance.

Key factors to consider when selecting a DC contactor

1. Rated voltage and rated current

Rated voltage: Must equal or exceed the maximum voltage of the charging system (typically 400V-1000V for fast chargers).

Rated current: Should support the peak current of the charger (e.g., 100A-500A for high-power DC chargers).

2. Breaking capacity

DC arcs are more difficult to extinguish than AC arcs, so the contactor must have sufficient *breaking capacity* to safely interrupt high DC currents.

3. Pole configuration

Single-pole (SPST): For simpler circuits.

Double-pole (DPST): Provides additional isolation for safety.

4. Coil voltage and power consumption

Contactor coils should match the control circuit voltage (e.g., 12V, 24V, or 48V).

Low-power coils reduce energy consumption in standby mode.

5. Arc extinguishing technology

Magnetic blowout: Uses a magnetic field to stretch and extinguish the arc.

Arcing grid: Diverts and cools the arc to prevent damage.

6. Life and durability

Look for high mechanical and electrical durability (e.g., 100,000+ operations).

Sealed contactors are dust and moisture proof, making them ideal for outdoor charging stations.

7. Safety Certifications

Ensure compliance with the following industry standards:

UL 508 (Industrial Control Equipment)

IEC 60947 (Low Voltage Switchgear)

Automotive standards (e.g. ISO 8820)

8. Size and Mounting

Compact design saves space in charging cabinets.

DIN rail or screw mounting options available for easy installation.

9. High Temperature and Environmental Resistance

The operating temperature range should be suitable for the installation environment (-40°C to +85°C for outdoor use).

Use corrosion-resistant materials for harsh conditions.

10. Manufacturer Reputation and Support

Choose a reputable brand with reliable technical support (e.g. TE Connectivity, Gigavac, Siemens).

Common Applications for EV Charging

DC Fast Chargers (50kW–350kW)

Battery Management Systems (BMS)

EV On-Board Chargers

Energy Storage Systems (ESS)

Conclusion

To select a DC contactor for EV charging, consider the system's voltage and current requirements, ensuring the contactor can handle the maximum load with sufficient safety margins. Look for high breaking capacity to manage potential fault currents, and choose a contactor with low power loss and reliable arc suppression for efficiency and longevity.

For high-power DC fast charging, investing in high-quality contactors from a reliable manufacturer is critical to preventing failures and improving reliability.

English

English  한국어

한국어